Determination of fibre release during textile care and in waste water

Up to 500,000 tonnes of microplastic fibres enter the world's oceans every year. During the production of textiles as well as through use and washing, fibre fragments are released from synthetic textiles. If these are not effectively removed by downstream cleaning processes, they enter rivers, inland waters and oceans via wastewater.

Measure – Understand – Reduce

DIN SPEC 4872 - Analysis of Fibre Release During Washing of Textiles

DIN SPEC 4872

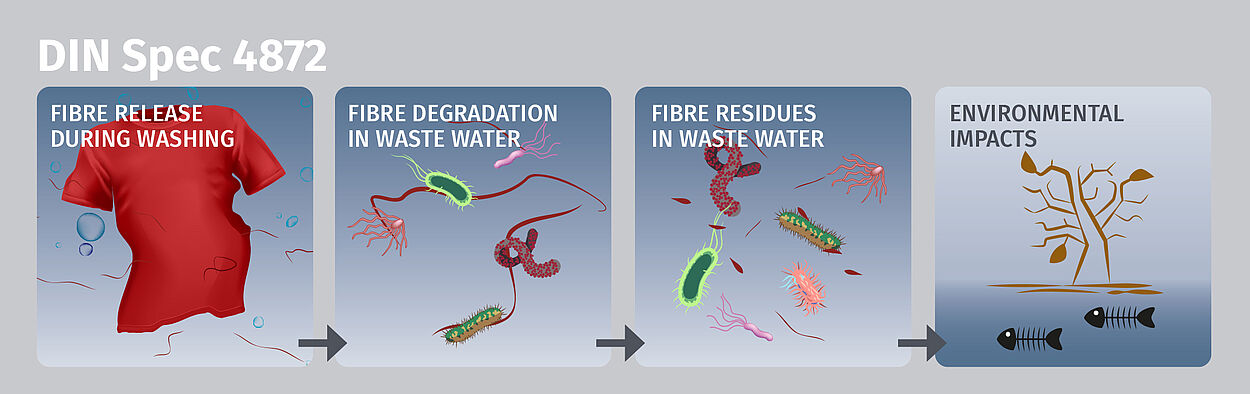

The new DIN SPEC 4872 is a standardised test method for determining and classifying the environmental impact of textiles during washing. The test method examines how many fibres are discharged when textiles are washed, how well these fibres degrade in wastewater and how harmful the fibre residues are to the environment.

Once the test has been completed, we assign a classification code as a result, which reflects the degree of fibre discharge, the biodegradation rate and the ecotoxicological potential of the textile product under investigation.

Download DIN SPEC 4872

DIN SPEC 4872 to the point

Our webcast introduces you to our holistic approach to determining fibre release during washing, biodegradation and ecotoxicity.

We perform these tests for you

Your benefit as a customer

- Objective measurement of fibre discharge during washing, biodegradability and the ecotoxicological potential of fibre residues

- Competent and independent evaluation, comparison and improvement of your sales articles

- Determination of the environmental benefits and risks of your products

The aim of our assessment is to provide you with reliable data for an optimisation of your product portfolio and a more targeted product development, which allows you to actively and consciously control or avoid environmental pollution.

Microplastic Analysis of Textiles & Production Wastewater

Our test methods

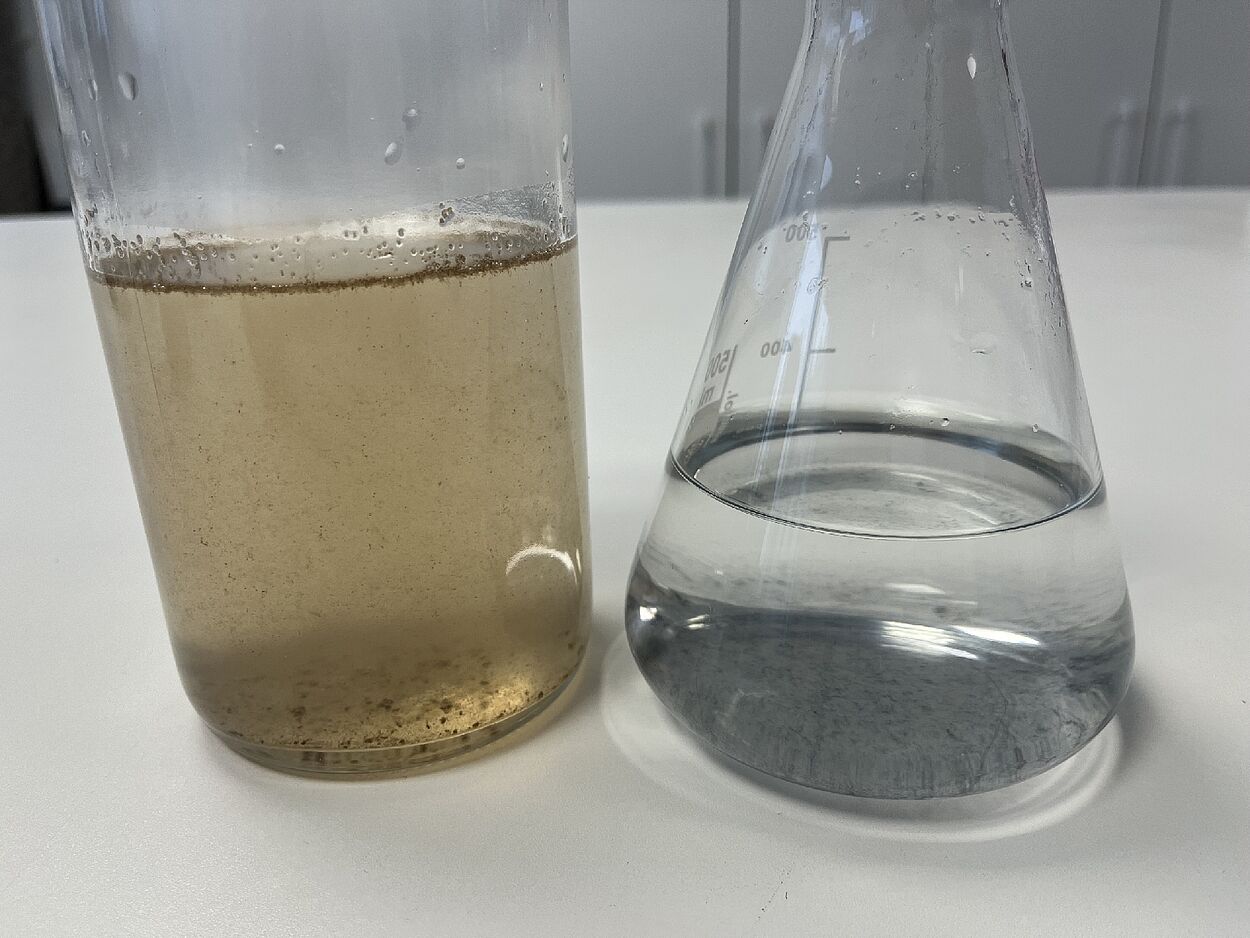

With our analytical methods, we determine the fibre release behaviour from textile surfaces and the fibre content in process and waste water for you.

- Quantification of fibre release and fibre length distribution with the Hohenstein method: Dynamic Image Analysis (DIA)

- Gravimetric measurement of total abrasion by filtration according to the University of Leeds / Microfiber Consortium (UoL/TMC) method, AATCC TM212 or DIN EN ISO 4484-1

Don't miss this advantages.

- Analyses of textiles and waste water (various sample types from a single source)

- Determination of amount, type and shape of released fibres by Hohenstein method DIA

- Objective measurement of fibre release

- Quality control of waste water, optimisation potential of existing processes and processing steps

Hohenstein is driving textile sustainability forward with intensive research.

When considering the environmental impact of textiles, there is no way around microplastics. Hohenstein has been at the forefront of this research since 2016. Benefit from our active involvement in research and standardisation committees.

Test kit for textile microfibre shedding

In cooperation with Under Armour testing provider Hohenstein is launching a new fiber-shed test kit. It will help textile companies along the supply chain to develop lower shed materials during product development. Our video instructions explain how companies can use the kit in an easy-to-understand way.